DIN 963-90

Senkschrauben mit Schlitz Supersedes April 1985 edition

In keeping with current practice in standards published by the international Organization for Standardization (ISO), a comma has been used throughout as decimal marker.

This standard should be used together with ISO 2009. For details, see Explanatory notes, It id intended to withdraw the present standard by 31 July 1995 at the latest.

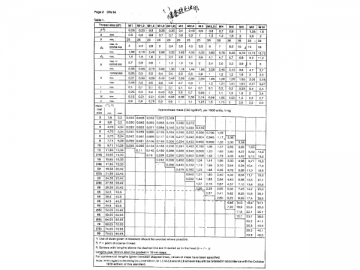

Dimensions in mm

1 Scope and field of application

This standard specifies requirements for M1 to M20 slotted countersunk head screws assigned to product grade A. See DIN 962 (or the standards to therein) for special screw types or finishes.

If, in special cases, screws are to company with specifications other than those given in this standard (e.g. regarding property class or material ), these shall be selected in accordance with the relevant standards.

2 Dimensions

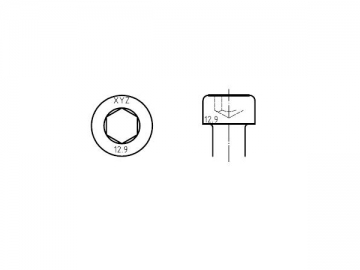

Countersunk head screw

Threaded up to the head

(specified in table 1 above dashed line)

Countersunk head screw with unthreaded portion of shank

(specified in table 1 below dashed line)1)

The shank diameter may be equal to the thread diameter (normal shank) or approximately equal to the pitch diameter (reduced shank), at the manufacturer’s discretion.

1) If countersunk head screws with lengths given below the dashed line are to be supplied with their shank threaded up to the head, letter A shall be included in the designation, in accordance with DIN 962.

Page 2

4 Designation

Designation of an M5 countersunk head screw, of length L (nominal size) =

Countersunk head screw DIN 963-M5×20-4.8

DIN 962 shall apply for the designation of type and finishes with additional information to be give on ordering. DIN 7500 Part 1 shall apply for thread rolling screw and DIN 7513, for thread cutting screw.

The DIN

Standards referred to

DIN 13 Part 13 ISO metric screw threads; series of preferred sizes for screws, bolts and nuts from

DIN 13 Part 15 ISO metric screw threads; fundamental deviations and tolerances for screw threads of

DIN 78 Thread ends and lengths of projection of bolt ends for ISO metric screw threads in accordance with DIN 13

DIN 267 Part 1 Fasteners; technical delivery conditions; general requirements

DIN 267 Part 2 Fasteners; technical delivery conditions; design and dimensional accuracy

DIN 267 Part 5 Fasteners; technical delivery conditions; acceptance inspection(modified version of ISO 3269, 1984 edition)

DIN 267 Part 9 Fasteners; technical delivery conditions; electroplated parts

DIN 267 Part 11 Fasteners; technical delivery conditions; technical delivery conditions; with addenda to ISO 3506; stainless and acid resistant steel components

DIN 267 Part 18 Fasteners; technical delivery conditions; non-ferrous metal components

DIN 267 Part 19 Fasteners; technical delivery conditions; surface discontinuities on bolts

DIN 962 Bolts, screws, studs; designations, types and finishes

DIN 4000 Part 2 Tabular rolling screws for ISO metric threads; dimensions, requirements and testing

DIN 7500 Part 1 Thread rolling screws for ISO metric threads; dimensions, requirements and testing

DIN 7513 Hexagon head and slotted head thread cutting screws; dimensions and

DIN 898 Part 1 Mechanical properties of fasteners; bolts; screws; dimensions and studs

DIN 4759 Part 1 Tolerances for fasteners; bolts; screws and nuts with thread diameters from 1.6 to

Previous editions

DIN 963: 06.70, 04.85.

Amendments

The following amendments have been made to the April 1985 edition.

a) The title of the standard has been amended.

b) A note on the peziod of validity has been included.

c) X max values have been included in table 1.

d) The standard has been editorially revised.

Explanatory notes

In 1983, ISO 7721 was published in order to establish a common head style for all types of countersunk head screws. In the same year, a number of ISO Standards on metric countersunk head screws and countersunk head tapping screws with head styles complying with the specifications given in ISO 7721 were published in these standards, a countersunk angle of 90˚ was specified for both types of screw, this being a departure from the previous international specification of tapping screws with an 50˚ angle. The performance of screws with a 90˚ angle was verified in a number of tests. Although the decision to introduce the ISO common head style as established in ISO 7721 was made in 1977, it took quite a long time for this style to be adopted in national standards since ISO 7721 was primarily concerned with reducing the variety of screw heads but not with specifying other properties of such screws. Thus, in 1987, several countries, among them

Taking the international development into account, the responsible German committee came to the conclusion that adoption of the international specifications on countersunk head screw would be inevitable, and decided to issue national standards on countersunk head screws with ISO head, granting, however, an adequate transition period after which the relevant DIN Standards would be withdrawn.

The decision to adopt the ISO head was seen to be justified by the formation of CEN/TC 185, Fasteners, in 1989 since relevant European Standards dealing with such screws will be published shortly. Note that such EN Standards will be accepted only if they agree with existing ISO Standards, to avoid another transition and that the transition perioo mentioned on page 1 may be shorter if the EN Standards appear sooner that expected.

Page 6 DIN 963

The following table, which compares the most essential head dimenslong, dk and k, of screws as specified In ISO 2009 and the present standard, Is intended to make it easier for the user to see whether screws are interchangeable. The screws should be checked for interchangeability in cases where automatic feed and bolting systems are used.

Note. In order to facilitate the use of ISO 7721 countersunk head screws, a standard on mating countersinks, DIN 66, has been published.

International Patent Classification

F 16 B 35/04